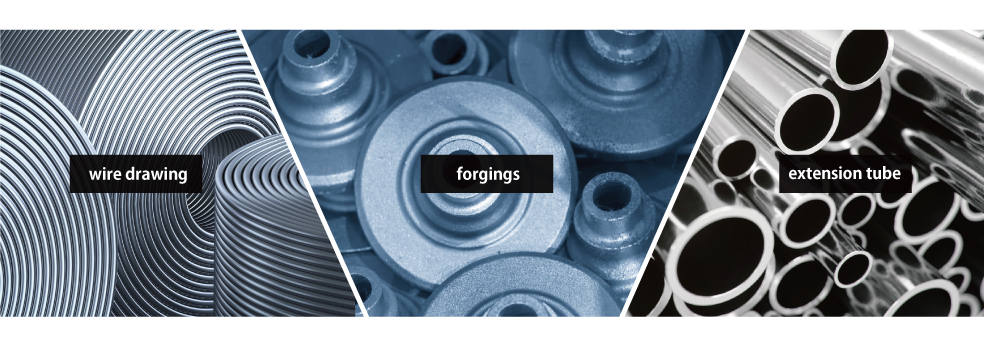

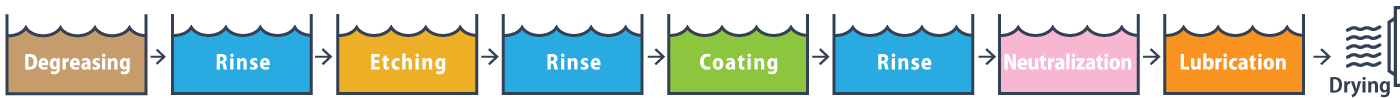

These are surface treatment agents related to lubrication treatment for plastic working, mainly for steel and aluminum alloys. In the lubrication process, there are agents used in conventional processes that combine chemical conversion coatings and lubricants (reactive lubricants) and lubricants suitable for non-bonde lubrication that can significantly shorten the treatment process.

※We refer to applied lubricants as non-bonded lubricants. We also have a lineup of cleaning agents suitable for removing residual lubricant after processing.

Products

Reactive Lubricants

Phosphate film agent, soap-based/molybdenum disulfide-based lubricant

This is an agent that forms a chemical conversion coating as a base for the lubricating coating, and then forms a lubricating coating on the upper layer to form the optimum coating for cold forging.

Non-bonde Lubricants

We call one-process lubricants to Non-bonde lubricants.

This is a chemical that forms a film suitable for cold forging using only a lubricating film, omitting chemical conversion coatings. It is an effective agent for process shortening and cost reduction.

Plastic working related cleaning agents

Plastic working related cleaning agents

This agent is suitable for removing residual film from processed products.