CHEMICLEANER / CHEMISOL Series

From general purpose solutions to specialized strippers, we have the environmentally friendly products for various materials such as metals, glasses, and plastics.

Products

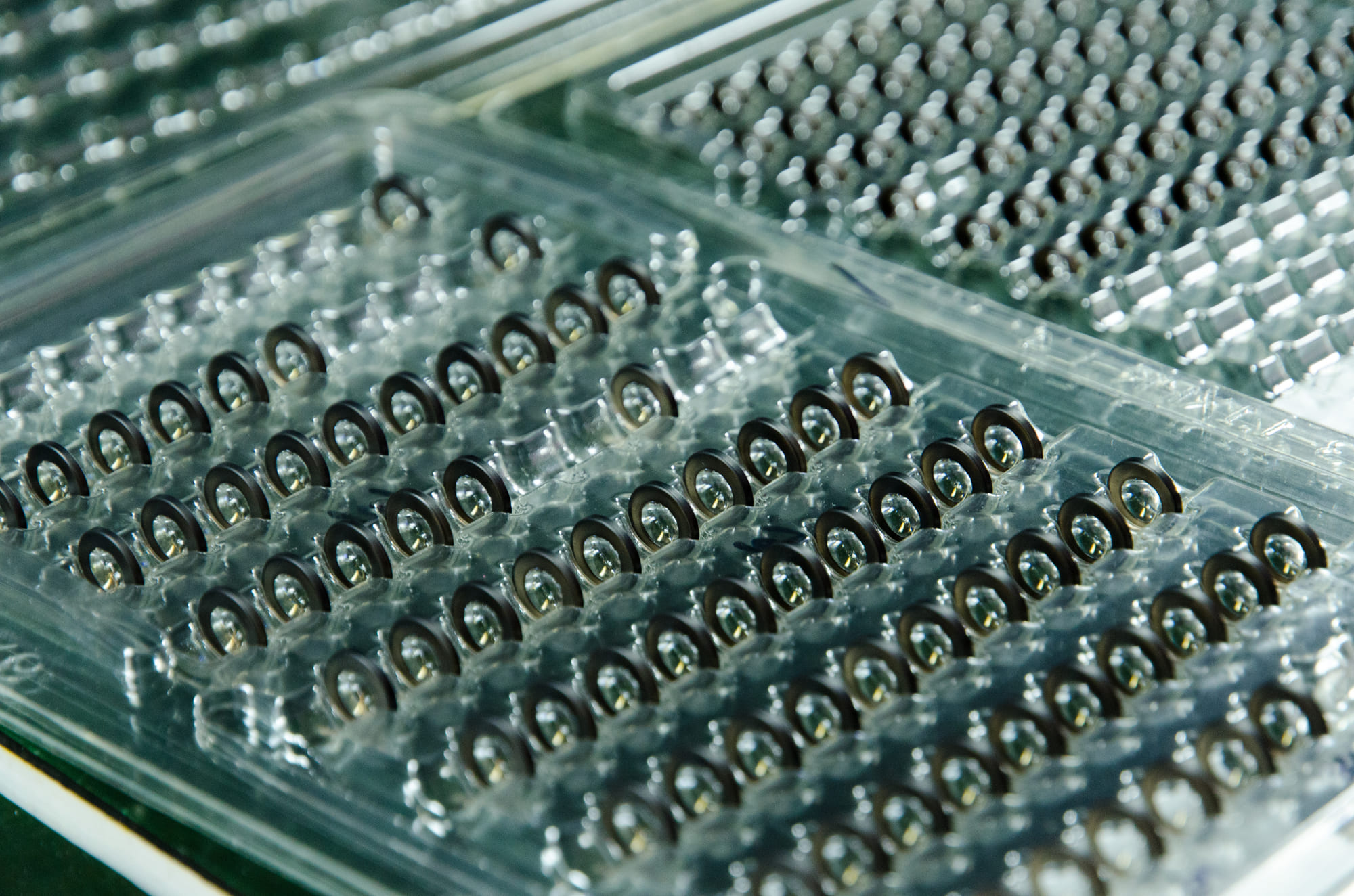

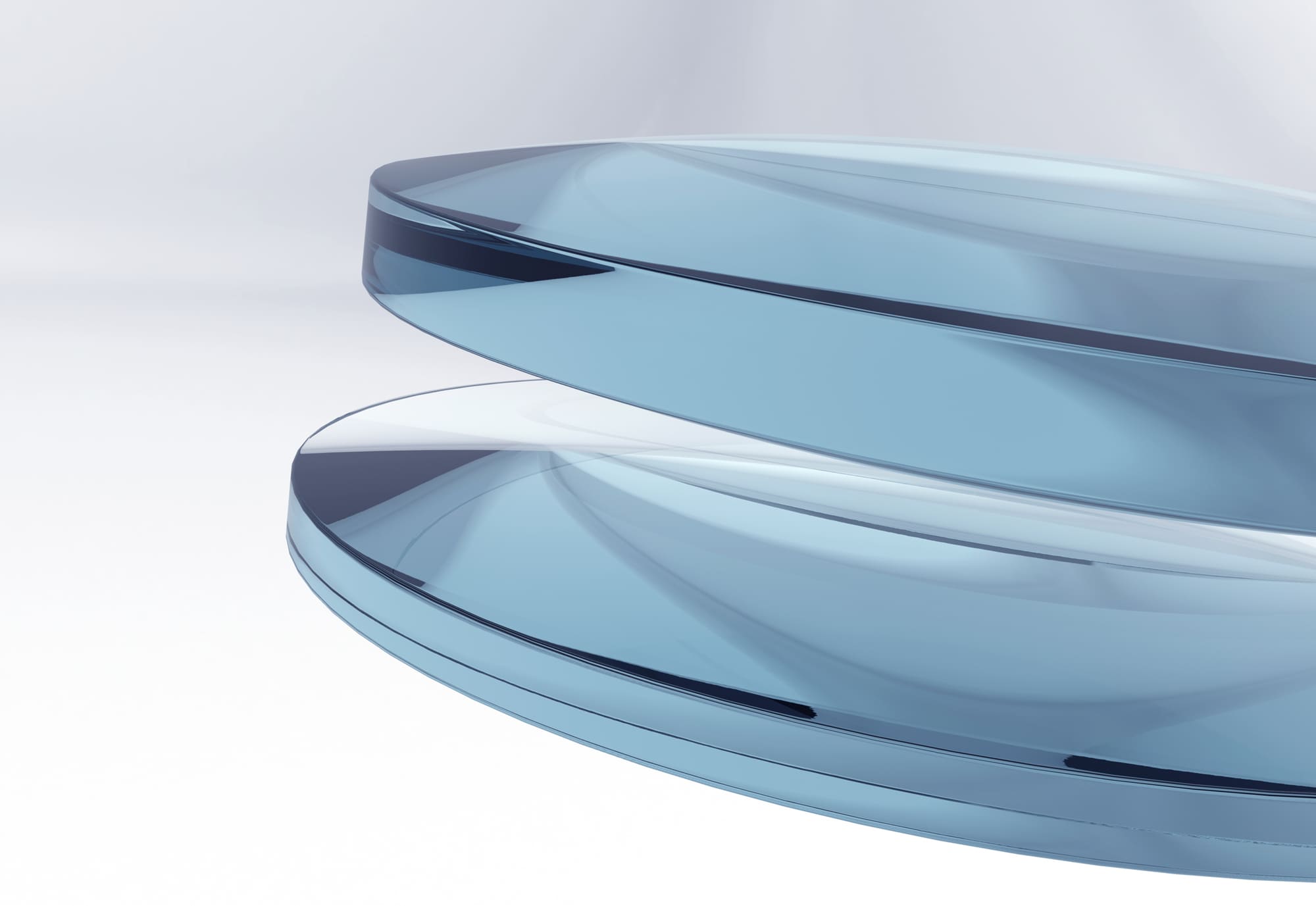

Optical Cleaner/Removers

CHEMISOL 2600

A semi-aqueous wax cleaner specially designed for cleaning pitch and wax protective coatings. Non-flammable and no chlorinated solvents.

CHEMISOL 2621E

A water-dilutable neutral wax cleaner specially designed for cleaning wax adhered after dicing, UV curable acrylic paint removal, and tape residue cleaning.

CHEMICLEANER 3721

A cleaner for centering cutting fluid specifically designed for degreasing and removing adhesives after processing optical parts (ex. glasses, plastics) .

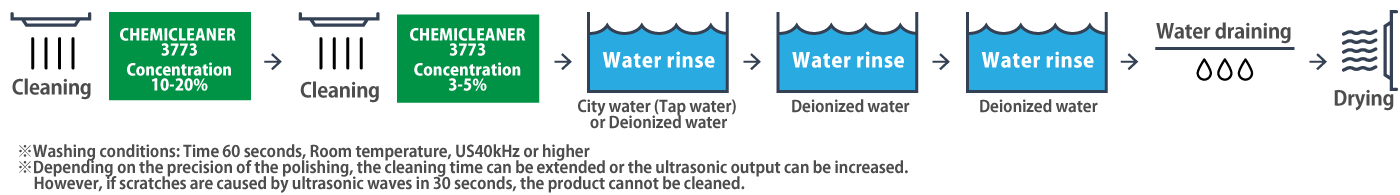

CHEMICLEANER 3773

A concentrated neutral cleaner specially designed for soft glass materials.

CHEMISOL 2315H

A general lens cleaner specially designed for removing YAKE and wide range of inorganic and organic contaminants such as abrasives, fingerprints, and minor white stains.

CS Clean

A pre-deposition cleaner specially designed for removing surface particles on soft glass, general glass, and flat glass materials. Also effective for pre-cleaning of multilayer films.

CHEMISOL 2316

A cleaner specially designed for removing YAKE (water YAKE after storage, paper YAKE, etc.), fingerprints and abrasives on flat glasses, BK7, quartz, etc.

CHEMISOL 2620H

A cleaner specially designed for removing YAKE (water YAKE after storage, paper YAKE, etc.), fingerprints and abrasives on soft glass materials , etc.

CHEMISOL 2318

A coating remover specially designed for optical thin film on optical components and vapor deposition fixtures.

CHEMISOL 2602

A neutral optical paint remover specially designed for GT-7Ⅱ and black ink.

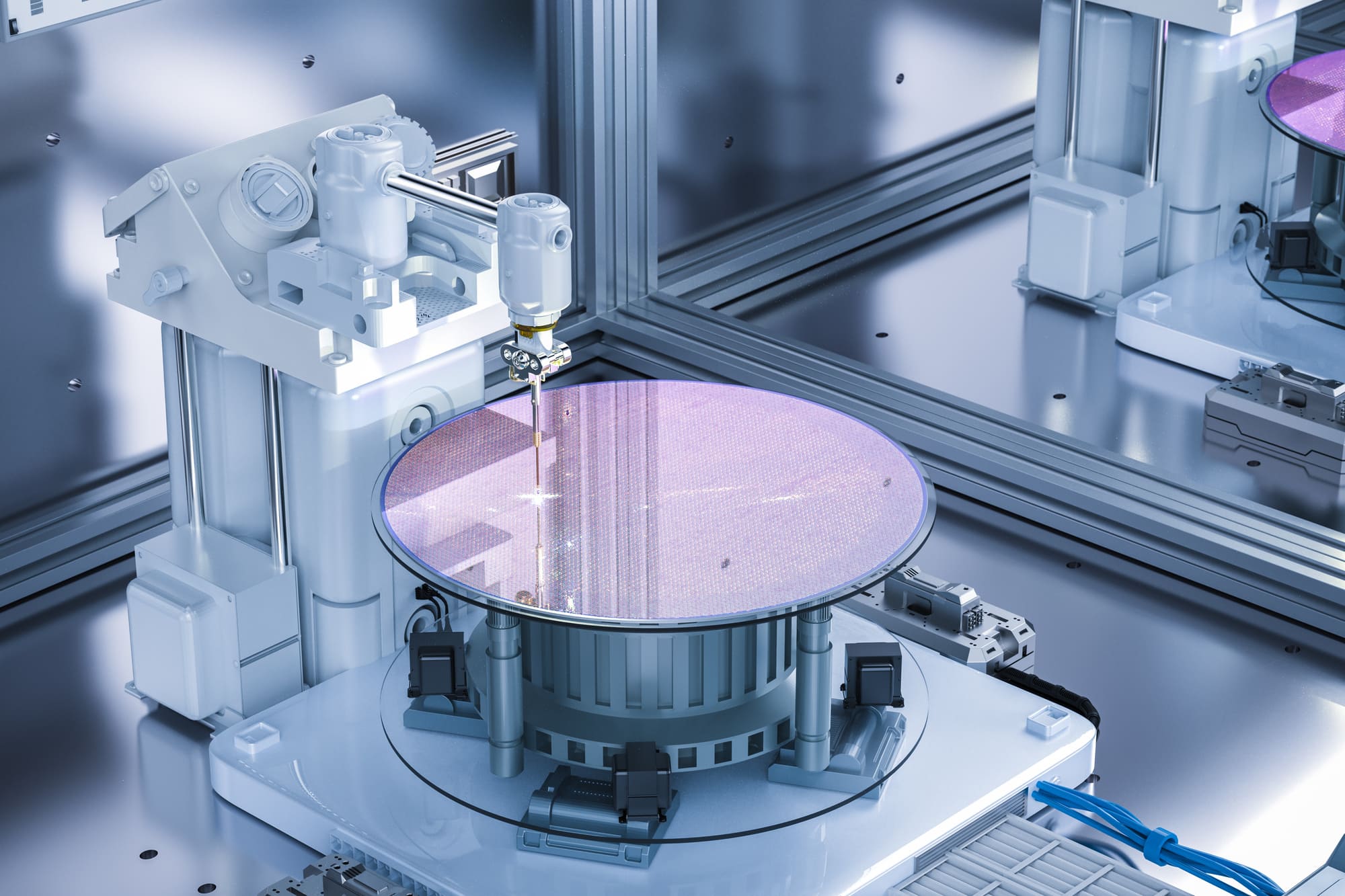

Removers for Nanoimprint lithography

CHEMISOL 2611

A neutral remover specially designed for UV curable acrylic resin adhering to Ni electroforming and other molds.

CHEMISOL 2610

A weak alkaline remover specially designed for UV curable acrylic resin adhering to Ni electroforming and other molds.

CHEMISOL 2303

A strong alkali remover specially designed for epoxy resin adhering to Ni electroforming and other molds.

Plastic Lenses Cleaner/Removers

CHEMISOL 2405

A general purpose cleaner and remover specially designed for cleaning chips and monomer stains after plastic lens processing. Also effective as a remover for epoxy resins and paints in general.

CHEMICLEANER 3555

A mold and dyeing jig cleaner specially designed for resins(thermosetting resins and urethane resins) on glass molds.

CHEMISOL 2303

A coating remover specially designed for AR coatings (anti-reflection coatings) and hard coat coatings on highly refractive components. Can also be used for light degreasing purposes.

CHEMISOL 2313

A coating remover specially designed for AR coatings (anti-reflection coatings) and hard coat coatings on highly refractive components. also be used for removing coatings on SUS jigs.